Products

Spectra-1 Open Path Gas Monitor – Industrial & Environmental

Spectra-1, a portable lightweight open path TDLAS gas monitor uses proprietary hardware and software to provide a low cost open path gas sensing instrument. The enclosure for Spectra-1 was selected for its resistance to extreme shock and vibration. Spectra-1 can be used for portable as well as fixed site installations. RS232 serial communications are used for continuous data transfer. USB memory stick data downloading is used for logged data files. Applications include environmental monitoring, fugitive emission work, greenhouse gas reduction, fertilizer manufacturing, Ammonia, confined feeding operations monitoring, aluminum manufacturing HF monitoring, and landfill monitoring.

Applications

- Aluminium Manufacturing

- Fertilizer Production

- Confined Feeding Operations

- Environmental Monitoring

- Greenhouse Gas Reduction Programs

- Cold Storage, Ice Rinks

- Landfill Operations

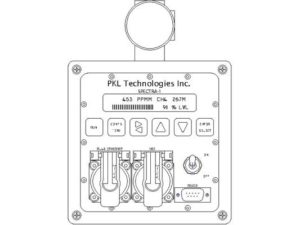

Spotting scope:

- Spectra-1 alignment with retro-reflector

- 2 X 20 character LCD display:

- gas concentration

- ppm or ppm-m

- distance to retro-reflector

- signal level bar graph

- signal level % reading

- configuration/menu display

Keypad for system configuration:

- distance to retro-reflector

- gas concentration - ppm or ppm-m

- averaging time 1 to 600 seconds

- maximum signal level set (i.e. 90%)

- minimum signal level set (i.e. 5%)

- RS232 com port setting (baud rate)

- logging options

- logged data transfer – USB memory stick

- calibration settings (Factory set)

- Spectra-1 settings output

- display IP address

RJ45 Ethernet weatherproof connector

USB weatherproof connector

Sealed on/off power switch

Sealed RS232 com port

12 VDC @2A

Spectra-1 Extractive Gas Monitor – Industrial & Environmental

Spectra-1 Extractive gas monitor features the same gas analysis software as used by the open path Spectra-1 monitor. Tuneable Diode Laser Absorption Spectroscopy (TDLAS) based gas sensing. Closed path internal multi-pass sampling cells are used instead of an open path configuration to calculate gas concentrations. 19' rack mounted design. Options include internal sampling pump and 4-20mA output. Standard configurable RS232 data output.

Features:

- gas specific - no false alarms

- fast response

- no water interference

- reliable unattended performance

- broad dynamic range

- direct measurement of gas species - not indirectly inferred

- no consumables or moving parts

- software upgrades for performance enhancements

- lower cost

- keypad For System Configuration

- internal multi pass optical sampling cell

- gas concentration - ppm or ppm-m

- averaging time 1 to 600 seconds

- maximum signal level set (i.e. 90%)

- minimum signal level set (i.e. 5%)

- RS232 com port setting (baud rate)

- logging options

- calibration settings (Factory set)

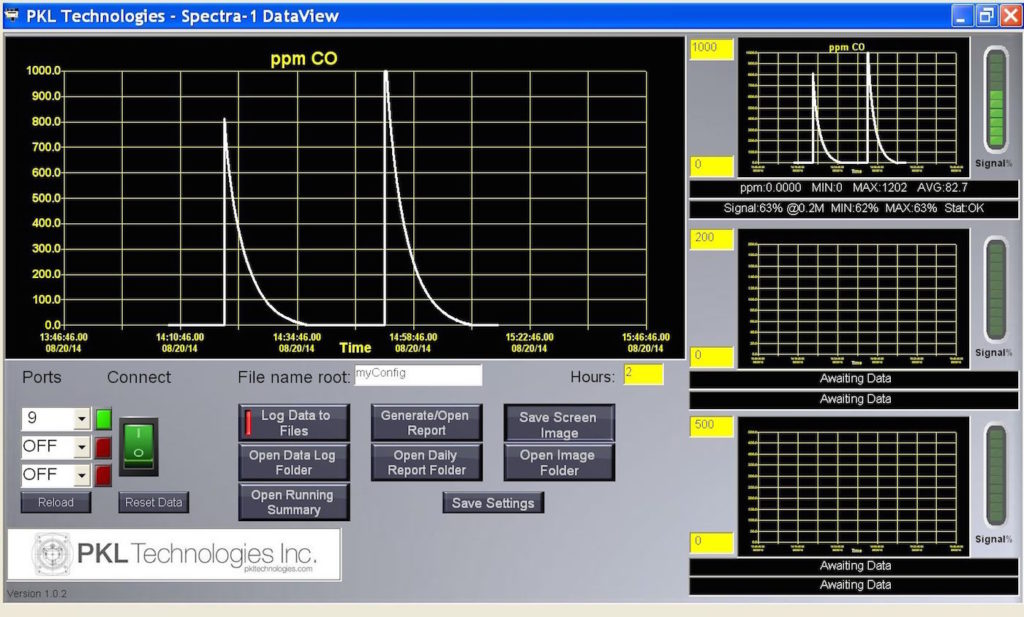

Spectra-1 DataView Program for Data Display and Logging

Spectra-1 Extractive gas monitor features the same gas analysis software as used by the open path Spectra-1 monitor. Tuneable Diode Laser Absorption Spectroscopy (TDLAS) based gas sensing. Closed path internal multi-pass sampling cells are used instead of an open path configuration to calculate gas concentrations. 19' rack mounted design. Options include internal sampling pump and 4-20mA output. Standard configurable RS232 data output.

Operating Notes:

Ports

- The Port Numbers are loaded automatically with available ports OR with the last saved configuration. Clicking Reload will close all connections and reload the available ports in all 3.

- All ports are pre- configured for 9600 8-N-1.

Connect & Indicators

- The Connect button will attempt to open all selected ports.

- Any connections that could not be opened will sound an alarm (bell), keep the indicator red, and log an error to the daily error file contained in the data directory.

- Opened connections will turn the indicators green.

- Arriving data on the respective port will turn the indicator yellow for a moment.

Data Errors

- Data errors, such as framing errors, will turn the indicator red for a moment, sound the bell, and log an entry to the daily error file contained in the data directory.

- After 3 consecutive packet errors, that port's input is flushed and the unprocessed data for the port is cleared.

Timeout Error

- Should data not arrive within 35 minutes on an open port, the respective plot's Signal information textbox will turn red (background) and the date/time of the last data will be shown as the message.

- An alarm will sound every 5 seconds.

- Changing/reconnecting to port number will clear the alarm for another 35 minutes. The box will go black again, and arriving data will clear the message.

Reset Data

- Reset Data button will reset the plots, the MIN/MAX/AVG, and reset the start time of data acquisition for the daily report.

Logging

- File name root allows the user to select a root name for the configuration which will be used in all files created. Use no commas, slashes or other non-standard filename characters in the names.

- Log Data to File

1. When ON (Green), raw incoming data will be saved to respective data files.

2. A new summary line of the day's values will be saved to the running summary within seconds of midnight.

3. A daily text report will be generated and saved within seconds of midnight. The time of starting data collection is reset. The MIN/MAX/AVG is reset for the day. - Open Data Log Folder will open the folder containing the raw data files.

- Open Running Summary will open the line-entry file (#2 above). This file is maintained in the "Reports" folder.

- Generate/Open Report will generate a new text report of tracked data, saved to the "Reports" folder, and opened in NotePad. The time of starting data collection is NOT reset nor are MIN/MAX/AVG.

- Save Screen Image generates a JPG file of the screen as seen (snapshot).

- Open Image Folder opens the snapshots folder for review.

Save Settings

- Save Settings will store to the computer's registry the current values for port numbers, state of log data button, file name root, hours, and plot Y-min/max settings. These values are reloaded when DataView is re-opened.

Hours

- Selects the number of hours to plot. Enter a value and either TAB off or hit enter.

Plot Y-Values

- Selects the number of Y-axis span to plot. Enter a value and either TAB off or hit enter.

Plots

- Click a plot to show that plot in large-view.

Information Text

- Top text box shows species, concentration values and statistics.

- Bottom shows the signal level, distance (path length), statistics, and status.

- Should the status not be OK (0x00000001), the text will turn red, until OK, then will turn Black.

Other status:

NONE

LOW

HIGH

H/L (erratic - High and low)

FULL (Spectra-1 log full) - This status box is also used for timeout error indication (see above)

- Should the status not be OK (0x00000001), the text will turn red, until OK, then will turn Black.

Signal %

- Graphically shows the signal level with color indicator:

- >90 %, Yellow

- 10% - 90%, Green

- <10%, Red

Plotted Data Discussion

A plot is redrawn when either:

- The DataView window is resized.

- The time reaches the X-maximum, at which point it will shift back 75%

- The time or Y-Axis values are changed.

Due to the time involved to redraw all stored data, only the last 6000 points are kept in memory. This allows a redraw in several seconds. For each reading received, 2 points are saved. Based on this, the total time maintained in memory can be found by (assuming all Specta-1's are set for same time averaging):

Number of hours = 6000 * averaging time / 2 data points each / 3 units / 60 seconds / 60 minutes.

So, if 3 units send data every 1 second: 6000 x 1s /2 /3 /60 /60 = 0.278 Hours

Or, averaging time x .278 hours (based on 3 units, equal averaging times)

On a plot redraw, this is the maximum time that of old data that will be redrawn

Customized Gas Sensors

PKL Technologies Inc. is capable of custom modifications to our existing gas sensors. We are also able to use the core gas sensing

hardware to design a completely new custom gas sensor. One examples being a new lightweight low power consumption gas sensor for UAV applications.